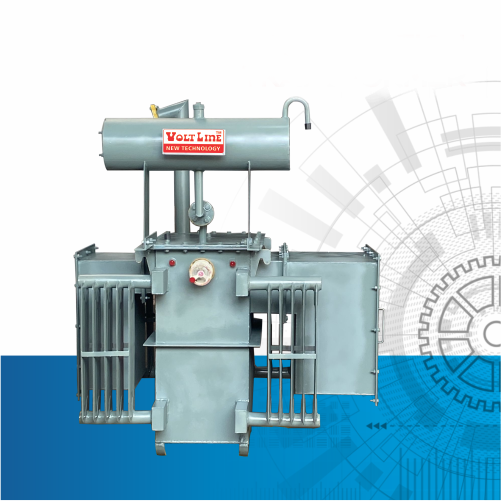

Distribution Transformers

Volt Line Brand offers a wide range of Power Distribution Transformers with conforming to the standards IS 2026/1977, IS 1180/1969, IEC 60076 or as per customer’s custom requirement. These transformers are designed and developed using latest technologies and can be provided with a variety of terminations so as to suit the requirements for new installation or replacement. The designs are so chosen that the total cost including material, maintenance and the energy cost due to no load and load losses are minimum Copper Winding: The most significant material in a transformer is the winding which comprises of rectangular and round conductors used for winding. The conductor is usually insulated with either high-grade multi- paper covering or with an insulating enamel coating. The windings are designed so as to ensure reduced axial stresses during Short Circuit conditions and withstand impulse and over- voltages. Some standard forms of coil winding are Spiral, Helical, Cross-Over and Disc winding. For Power Transformers, both low voltage and high voltage winding are Disc type, which give highest resistance against short circuits. It is ensured proper tension is given on the winding for rigidness. After receiving Copper conductor it will undergo Quality checking, Conductivity test (Resistance test) and during winding continuity of parallel conductors will also be checked. Coil Tightening: Winding coils are compressed to the designed heights after the insulation is dried for specified duration to ensure their proper shrinkage to designed level. For higher rating transformers compressing is done by hydraulic press with suitably designed clamping fixtures.